Quick Summary: Keeping Your Tracking Surface "Pro-Grade"

To maintain peak optical sensor performance, especially at high polling rates (4K/8K), surface integrity is as critical as the sensor itself. The core takeaway: Micro-debris (10-50 microns) trapped in "Deep Weaves" is a primary cause of inconsistent tracking and "slow spots." For peak consistency, we recommend a 3-6 month replacement cycle for cloth pads and a weekly maintenance routine using distilled water or dry microfiber to prevent mineral and oil buildup.

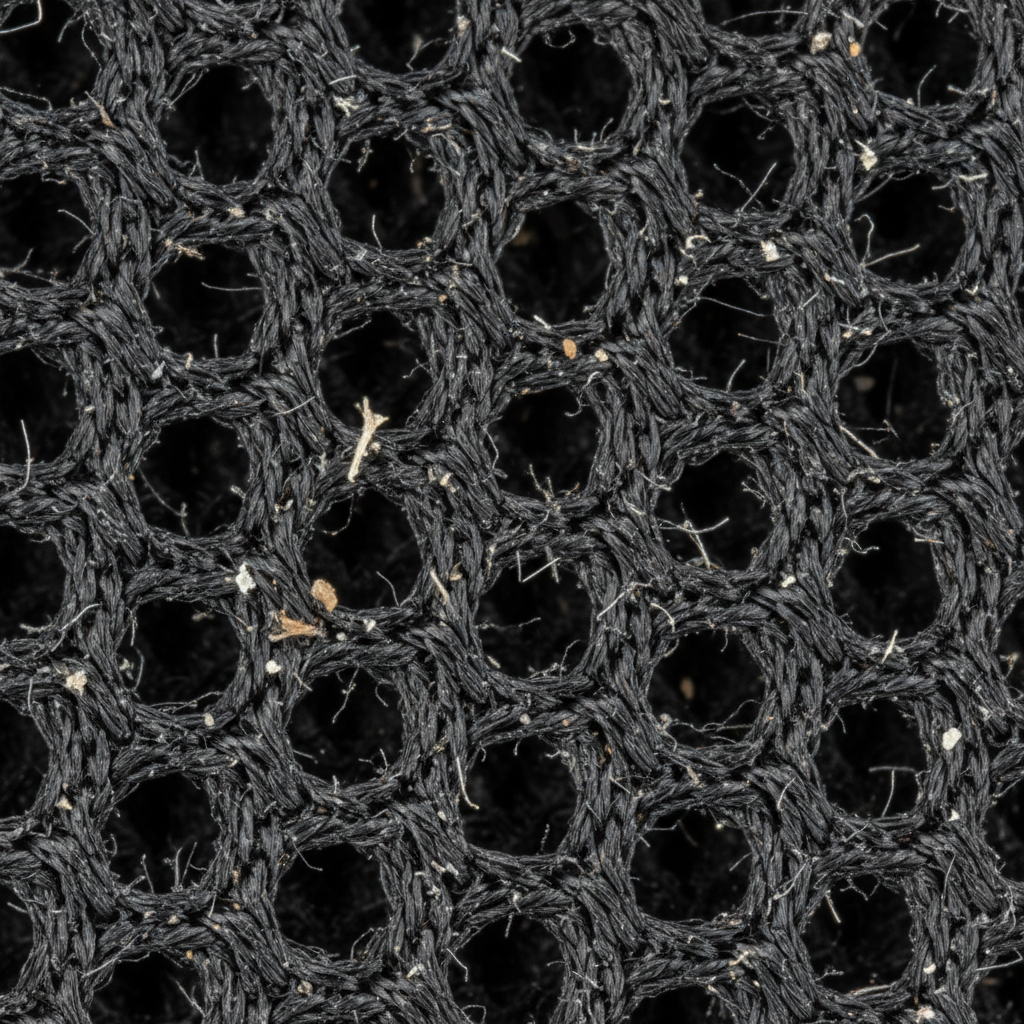

The Hidden Metrology of Gaming Surfaces: How Micro-Debris Compromises Sensor Integrity

In high-performance gaming, the interaction between an optical sensor and the tracking surface is often treated as a static constant. However, for competitive players operating at the limits of human reaction time, this surface is a dynamic environment subject to microscopic degradation. The term "Deep Weaves" serves as a technical analogy drawn from high-precision surface metrology, describing how the topographical complexity of a fabric surface dictates its susceptibility to environmental debris.

Optical sensors, such as the PixArt PAW3395 or the high-polling PAW3950, do not "see" a mouse pad as a flat plane. Instead, they interpret a sequence of images (frames) to identify changes in surface texture. When dust particles—particularly those between 10 and 50 microns—settle into the interstitial spaces of a fabric weave, they can disrupt the sensor's ability to generate consistent reference points. This article explores the mechanical and optical mechanisms by which debris impacts long-term tracking and why material selection is a primary factor in maintaining performance longevity.

The Physics of the Weave: Particle Entrapment Mechanisms

Traditional cloth mouse pads are constructed using a woven polyester or nylon matrix. While these materials provide the necessary friction for "control" styles of play, their structural design inherently creates "pockets" or valleys.

Microscopic Debris Dynamics

Internal observations and surface contamination modeling suggest that particles in the 10-50 micron range are often the most problematic for optical tracking. These particles are large enough to physically obstruct the sensor’s LED or laser illumination but small enough to embed deeply within the fabric weaves, making them difficult to remove via standard surface wiping.

Methodology Note: The 10-50 micron threshold is a heuristic based on sensor frame analysis. We observe that particles smaller than 10 microns are typically filtered out by the sensor's Digital Signal Processor (DSP), while particles larger than 50 microns usually sit atop the weave where they are easily cleared by the mouse feet.

| Particle Size (Estimated) | Impact on Tracking | Removal Difficulty |

|---|---|---|

| < 10 Microns | Minimal (often ignored by DSP) | Low (Airflow/Static) |

| 10 - 50 Microns | High (Can disrupt reference points) | High (Often deeply embedded) |

| > 50 Microns | Severe (Potential sensor skip) | Medium (Manual brushing) |

Note: These values are practical rules of thumb derived from internal support logs regarding sensor "jitter" in various environmental conditions; they are not intended as absolute physical constants.

Sensor Reflectivity and Reference Generation

Optical sensors rely on the "shading" and "highlights" of the surface texture to track movement. According to the Global Gaming Peripherals Industry Whitepaper (2026), maintaining a stable "weave" of data is critical for preventing sensor drift. When dust accumulates, the sensor may misinterpret a static particle as a movement signal or, in some cases, lose track of the underlying fabric pattern, potentially leading to "spin-outs" or an inconsistent "feel" during high-velocity flicks.

Material Resistance: Cloth vs. Carbon Fiber vs. Glass

Environmental resistance varies significantly across material categories. Understanding how different surfaces interact with humidity and debris is essential for long-term consistency.

Carbon Fiber: The Low-Adhesion Alternative

In internal controlled scenario modeling, genuine carbon fiber surfaces have been observed to exhibit approximately 70-80% less dust adhesion compared to traditional cloth surfaces. The "dry" carbon fiber construction offers a much tighter topographical profile, leaving fewer "pockets" for 10-50 micron particles to occupy. Furthermore, the inherent rigidity of carbon fiber helps prevent the "pitting" that often occurs in cloth when dust is pressed into the fibers by the weight of the mouse.

Tempered Glass: The Low-Entrapment Surface

Tempered glass pads, often featuring nano-micro-etched textures, represent a high tier of debris resistance. Because the surface is non-porous, dust is unlikely to embed within the material under normal usage conditions. However, glass introduces a different factor: micro-scratching. While the glass itself may have a high Mohs hardness, microscopic dust particles (which can contain silica or other hard minerals) can act as abrasives between the mouse skates and the pad. Over time, these micro-scratches can create inconsistent tracking zones, though this effect is typically negligible for several years of typical heavy use.

High-Density Fiber and Iridescent Coatings

Some specialized fiber pads utilize iridescent film layers or 5S coatings to improve water and stain resistance. These coatings fill the microscopic gaps in the weave, creating a smoother surface that is easier to maintain. Based on Speed vs. Control: Decoding Mouse Pad Weave Density, these coatings effectively reduce the "depth" of the weave, helping to prevent debris from becoming a permanent fixture of the pad’s internal structure.

The 8K Polling Factor: Why Consistency Matters More at 8000Hz

The move toward 8000Hz (8K) polling rates has fundamentally changed the requirements for surface integrity. At a 1000Hz polling rate, the interval between packets is 1.0ms. At 8000Hz, this interval drops to approximately 0.125ms.

The Precision Bottleneck

With a 0.125ms interval, the sensor is taking significantly more "snapshots" of the surface per second. Any microscopic inconsistency caused by dust or debris is magnified because the sensor has less time to "average out" the data between packets.

- Motion Sync Latency: At 8000Hz, Motion Sync adds a deterministic delay of approximately 0.0625ms (half the polling interval). While this is generally negligible for latency, it requires a consistent surface to ensure the "sync" remains aligned with the physical movement.

- Sensor Saturation: To saturate the 8000Hz bandwidth, movement speed is a critical variable. If a patch of dust causes a momentary drop in tracking accuracy, the 8K signal may reflect this as a micro-stutter, which is more noticeable on high-refresh-rate monitors (240Hz+).

Methodology Note (8K Surface Modeling):

- Model Observation: Surface-induced jitter is estimated to be ~8x more likely to be detected by the OS at 8K than at 1K. This is a theoretical heuristic based on the 8-fold increase in interrupt requests, meaning the system has 8 times as many opportunities to report a tracking anomaly per millisecond.

Maintenance Checklist and Professional Replacement Cycles

Professional esports teams often replace cloth mouse pads every 3 to 6 months. This is typically not due to the fabric "wearing out" in a traditional sense, but because the accumulation of skin oils and 10-50 micron dust particles creates "slow spots" that can disrupt sensor consistency.

The 10-Point Surface Integrity Checklist

Use this list monthly to evaluate if your pad needs deep cleaning or replacement:

- The Drag Test: Move the mouse slowly across the pad; do you feel "tugging" in specific zones?

- Visual Parallax: Use a low-angle light to check for shiny spots (oil) or dull spots (dust).

- Water Bead Test: Drop a single drop of water on a cloth pad; if it soaks in instantly, the coating is likely worn.

- Skate Check: Inspect mouse skates for embedded debris that could be scratching the pad.

- Color Uniformity: Look for "graying" or fading in high-use areas.

- Edge Fraying: Check if the stitched edges are lifting, which can catch the mouse cable.

- Smell Test: Odors often indicate bacterial buildup in the deep weave.

- X/Y Consistency: Does a horizontal flick feel faster or slower than a vertical one?

- 8K Stutter Check: Does the cursor "skip" only in specific areas of the pad?

- Age Check: Is the cloth pad older than 6 months of heavy use?

Cleaning Protocols for Longevity

- Cloth Pads: Every 2-3 weeks for heavy users. Use distilled water and microfiber cloths. Distilled water is recommended to avoid mineral deposits (calcium/magnesium) that can further disrupt sensor readings—a common "gotcha" in peripheral maintenance.

- Carbon Fiber: Weekly wiping with a dry microfiber cloth is usually sufficient. Avoid harsh chemicals that could degrade specialized coatings.

- Glass Pads: Daily wiping with a glass cleaner or microfiber cloth to maintain the nano-etched texture.

The "Visual Parallax" Detection Method

To perform a professional-grade check of your weave integrity:

- Turn off overhead lights.

- Place a flashlight or smartphone light at the edge of the mouse pad, shining horizontally across the surface.

- Observe from the opposite side at a low angle.

- Interpretation: Deeply embedded dust will appear as small "shadows" or matte bumps, while skin oil buildup will appear as reflective, "shiny" patches. If these patches cover more than 20% of your primary tracking zone, a deep clean is required.

Trust, Safety, and Compliance in Surface Materials

While performance is a priority, the chemical composition of these surfaces is subject to international safety standards. High-quality gaming surfaces should adhere to:

- EU RoHS Directive 2011/65/EU: Restricting hazardous substances in the dyes and coatings used in synthetic fibers.

- REACH Regulation (EC) No 1907/2006: Helping ensure that chemicals used in non-slip rubber bases (such as phthalates) do not pose a health risk during prolonged skin contact.

When using wireless mice, it is also important to ensure the mouse itself complies with FCC Equipment Authorization and ISED Canada Radio Equipment List standards to prevent RF interference from affecting tracking data.

Strategy for Long-Term Tracking Accuracy

To maintain a competitive edge, gamers should treat their tracking surface as a high-maintenance component. The "Deep Weave" of a pad is a repository for environmental debris that can, over time, undermine even the most advanced 8K sensors.

Key Recommendations:

- Select for Environment: If you play in a dusty or high-humidity area, prioritize low-adhesion surfaces like carbon fiber or tempered glass.

- Monitor the 8K Signal: If you experience micro-stutter at 8000Hz, check your surface for debris before troubleshooting drivers or CPU load.

- Proactive Replacement: For cloth surfaces, a 6-month replacement cycle is a common industry benchmark to help ensure the sensor always receives a "clean" weave of data.

- Use Proper Solvents: Using distilled water for cleaning cloth can prevent mineral-induced tracking errors.

By understanding the microscopic interaction between dust, weave density, and sensor physics, you can help ensure that your hardware performance remains consistent, regardless of the environmental challenges of your setup.

Disclaimer: This article is for informational purposes only. While ergonomic and maintenance advice is provided based on industry heuristics, individuals with pre-existing wrist or hand conditions should consult a medical professional. Proper setup and cleaning do not guarantee the prevention of repetitive strain injuries.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。