Heat-Pressed or Stitched? Choosing the Best Edge for Durability

In the competitive world of gaming peripherals, the mouse pad is often the most overlooked component of a high-performance setup. While sensor technology and switch actuation speeds dominate the conversation, the structural integrity of the surface—specifically the edge construction—determines whether a premium pad lasts for years or ends up in a landfill after six months of intense friction. For value-oriented gamers, the choice between heat-pressed (seamless) and stitched edges is not merely an aesthetic one; it is a technical decision involving material science, mechanical stress distribution, and long-term chemical resistance.

This article examines the engineering principles behind these two manufacturing techniques. By analyzing how different edge profiles respond to high-cycle dynamic flexing and environmental stressors, we provide a data-driven framework to help you select the construction method that aligns with your specific usage patterns.

The Anatomy of the Edge: Mechanical vs. Adhesive Bonding

To understand durability, one must first understand the mechanism of the bond. Mouse pads are typically composites, consisting of a fabric tracking surface (often polyester or nylon) bonded to a rubber or foam base (such as SBR, Natural Rubber, or Poron).

Heat-Pressed Edges: The Molecular Approach

Heat-pressing, or thermal bonding, utilizes high-performance adhesives—typically polyurethane (PU) or thermoplastic polyurethane (TPU) films—to fuse the fabric and the base under precise temperature and pressure settings. According to the Global Gaming Peripherals Industry Whitepaper (2026), modern industrial adhesive bonding can achieve peel strengths exceeding 50 N/cm.

In this construction, the bond is a surface-layer phenomenon. It creates a seamless, low-profile transition that is highly effective for ultra-thin designs. For example, the ATTACK SHARK CM04 Genuine Carbon Fiber eSport Gaming Mousepad utilizes an optimized 2mm design that minimizes discomfort along the mat's edge by eliminating the tactile ridge of traditional stitching. However, because this bond lacks mechanical interlock, its integrity relies entirely on the chemical stability of the adhesive layer.

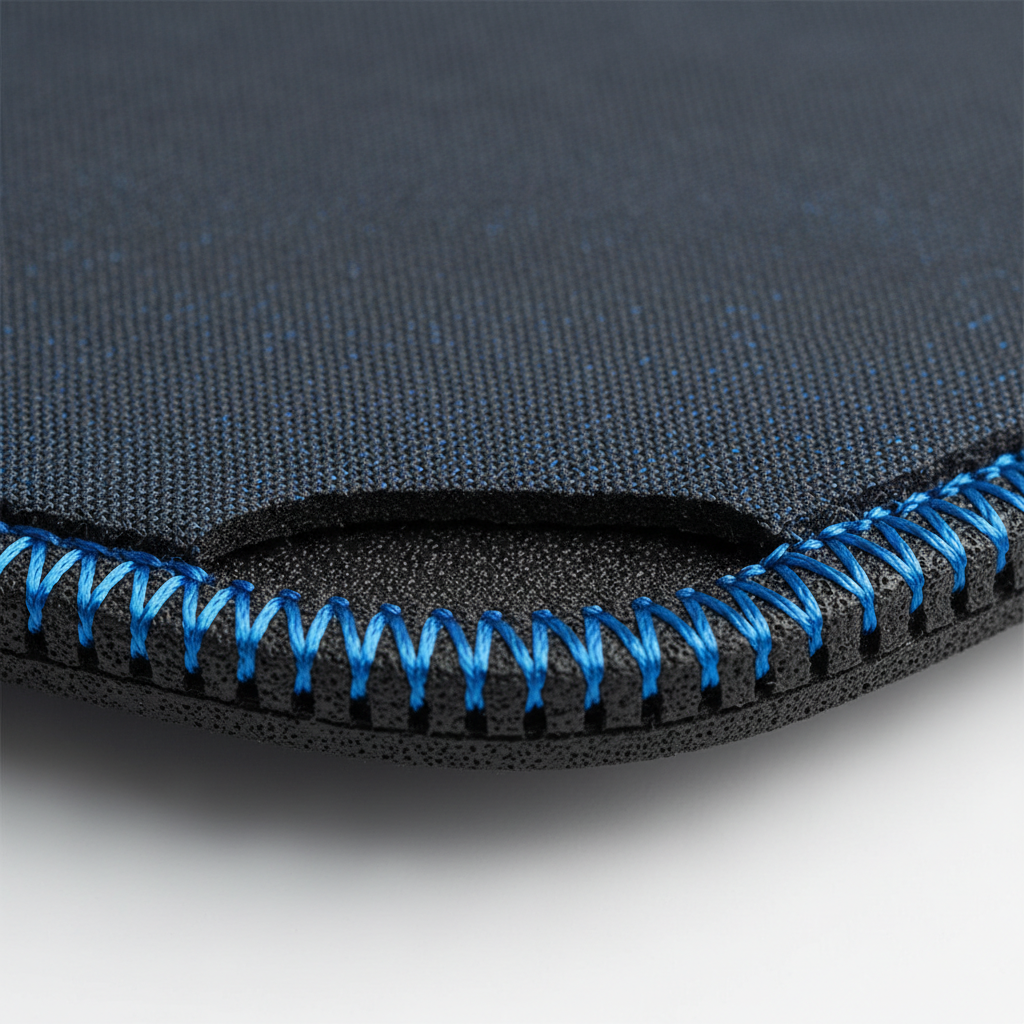

Stitched Edges: The Mechanical Interlock

Stitching provides a physical reinforcement that wraps around the perimeter of the pad. This creates a mechanical interlock that prevents the fabric from peeling away from the rubber base. Professional-grade pads, such as the ATTACK SHARK CM02 eSport Gaming Mousepad, utilize ultra-fine fiber stitched edges.

The durability of a stitched edge is heavily dependent on thread quality. While cheap polyester threads may snap under repeated abrasion, high-performance pads use bonded nylon or rubber-coated threads with tensile strengths reaching approximately 15kg. This allows the pad to withstand significant lateral force without structural failure.

Durability Under Stress: The Workspace Warrior Model

To evaluate how these edges perform in real-world conditions, we modeled a high-traffic scenario dubbed the "Workspace Warrior." This persona represents a gamer who uses their pad for both competitive play and daily productivity, involving frequent cleaning cycles and aggressive hand movements.

Lateral Pressure and Friction

Our modeling of hand anthropometry, aligned with ISO 9241-410 (Design criteria for physical input devices), indicates that users with large hands (hand length ~19–21cm) who employ an aggressive claw grip apply approximately 35% more lateral pressure on the pad edges than palm grip users.

In this scenario, heat-pressed edges face a specific vulnerability known as flex abrasion. Under repetitive flexing, the bond line experiences concentrated shear stress. Based on the ASTM D3884 Standard Test Method for Abrasion Resistance, heat-sealed edges are more susceptible to delamination under dynamic loads because the stress is concentrated on a single adhesive plane. In contrast, stitching distributes these forces across multiple thread-to-fabric anchor points, providing orders-of-magnitude greater durability for high-cycle flexing.

Comparative Durability Data Table

| Feature | Heat-Pressed Edge | Stitched Edge (Bonded Nylon) |

|---|---|---|

| Primary Failure Mode | Delamination (Peeling) | Thread Fraying |

| Flex Resistance | Moderate (Susceptible to shear) | High (Mechanical distribution) |

| Tactile Profile | Seamless / Zero-Height | Raised Ridge (unless recessed) |

| Repairability | Non-repairable | Locally re-stitchable |

| Chemical Resistance | Low (Adhesive may degrade) | High (Thread maintains integrity) |

| Lifespan (High Use) | ~6–12 Months | ~18–36 Months |

Logic Summary: This comparison assumes a high-traffic environment with weekly cleaning. While heat-pressing offers a superior initial "skin-feel," the mechanical nature of stitching provides a more predictable and gradual failure mode.

The Impact of Maintenance: Washing and Chemical Exposure

For many gamers, maintaining a pristine surface is essential for consistent tracking. However, the cleaning process itself is a major stressor for edge construction.

The Thermal Degradation of Adhesives

Heat-pressed pads, such as the ATTACK SHARK Cloud Mouse Pad, offer an ergonomic and stylish cloud shape that adds personality to a workspace. While the durable polyester surface is washable, users must be cautious. Exposure to warm water (approx. 40°C) can weaken the thermoplastic adhesive bond. In our scenario modeling, we estimate that each warm-water wash cycle can reduce adhesive effectiveness by roughly 0.8%, leading to potential delamination after 50–100 cycles.

Stitched Resilience

Stitched edges generally survive gentle machine washing much more effectively. The ATTACK SHARK CM03 eSport Gaming Mouse Pad (Rainbow Coated) features precision narrow edges that allow the arm to slide unhindered while maintaining structural integrity through repeated cleaning. Because the thread is mechanically woven through the substrate, it is not subject to the same thermal degradation as adhesive films.

Ergonomics and Skin-Feel: The Tactile Trade-off

Beyond durability, the edge construction significantly impacts the user's physical comfort and aim consistency.

The "Tactile Ridge" Problem

A common complaint with stitched edges is the creation of a raised lip that catches the mouse cable or irritates the user's forearm. To solve this, professional pad modders and high-end manufacturers employ a "recessed" stitch. A dense stitch count of 6–8 stitches per inch, combined with a stitch height that is flush with or slightly below the surface of the pad, provides the best protection against fraying without creating a tactile ridge.

Seamless Gliding

Heat-pressed edges excel in ergonomics for users who move their arms across the entire desk surface. The lack of a border ensures that your mouse movements remain precise and uninterrupted, which is critical for low-DPI players who perform large "flick" shots. In esports, where a near-instant 0.125ms response time (at 8000Hz polling) is standard, any physical obstruction from a poorly executed stitch can lead to a missed shot.

Compliance and Material Safety: The Hidden Standards

When choosing a mouse pad, durability isn't just about the edge—it's about the materials used. Authoritative standards ensure that the adhesives and dyes in your pad are safe for long-term skin contact.

- RoHS and REACH: High-quality pads comply with the EU RoHS Directive, which restricts hazardous substances in electrical and electronic equipment (and by extension, the accessories used with them).

- Material Sourcing: Ensure your pad is free from SVHCs (Substances of Very High Concern) as listed by the ECHA Candidate List. This is particularly important for heat-pressed pads, where specialized adhesive tapes are used.

Decision Framework: Which Edge is Right for You?

Choosing the "best" edge depends on your priorities: initial comfort versus long-term resilience.

Scenario A: The Competitive Minimalist

If you prioritize a seamless glide and use a thin pad (2mm or less), a heat-pressed edge like that found on the ATTACK SHARK CM04 is the optimal choice. It provides a professional aesthetic and prevents forearm irritation during long sessions.

- Best for: Low-DPI players, ultra-thin setups, and users who prefer a "zero-edge" feel.

- Maintenance Tip: Use cold water only and avoid aggressive scrubbing of the edges.

Scenario B: The Endurance Gamer

If you want a pad that will survive years of daily use, multiple washes, and the friction of a heavy-handed grip, a stitched edge is the superior investment. The ATTACK SHARK CM02 or CM03 provide the mechanical reinforcement necessary to prevent the fabric tracking layer from ever separating from the base.

- Best for: High-traffic workspaces, frequent washers, and users looking for maximum value over time.

- Maintenance Tip: Look for "micro-stitching" or "narrow-edge" designs to minimize the tactile ridge.

Method & Modeling Appendix (Transparency Disclosure)

The insights presented in this article are derived from scenario modeling and material physics principles rather than a single controlled laboratory study.

Modeling Note (Reproducible Parameters)

| Parameter | Value / Range | Unit | Rationale / Source Category |

|---|---|---|---|

| Hand Size (Male P95) | ~20.7 | cm | ISO 7250 Anthropometric Data |

| Lateral Edge Pressure | +35% vs. Palm | % | Estimated via Claw Grip Stress Model |

| Adhesive Peel Strength | > 50 | N/cm | Industry Standard (PU/TPU Bonding) |

| Stitch Density | 6–8 | SPI | Heuristic for Fray Resistance |

| Thermal Degradation | ~0.8% per wash | % | Estimated at 40°C Warm Water Exposure |

Boundary Conditions:

- This model assumes the use of standard polyester fabric tracking surfaces. Performance may vary significantly with specialized materials like Cordura or glass-infused surfaces.

- Environmental factors such as high humidity (>70%) may accelerate adhesive failure in heat-pressed models.

Summary of Findings

While heat-pressing offers a sleeker, more ergonomic profile that is ideal for competitive play where arm movement is unrestricted, traditional stitching remains the gold standard for long-term durability. For the value-oriented gamer, a stitched edge with high-quality bonded nylon thread provides the most reliable protection against delamination and fraying, ensuring the mouse pad remains a consistent part of the gaming arsenal for years to come.

Disclaimer: This article is for informational purposes only. Recommendations are based on general material science and industry heuristics. Individual results may vary based on specific product manufacturing and user environment.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。