The 'Ping' Phenomenon: Acoustics of Magnesium Alloy Gaming Mice

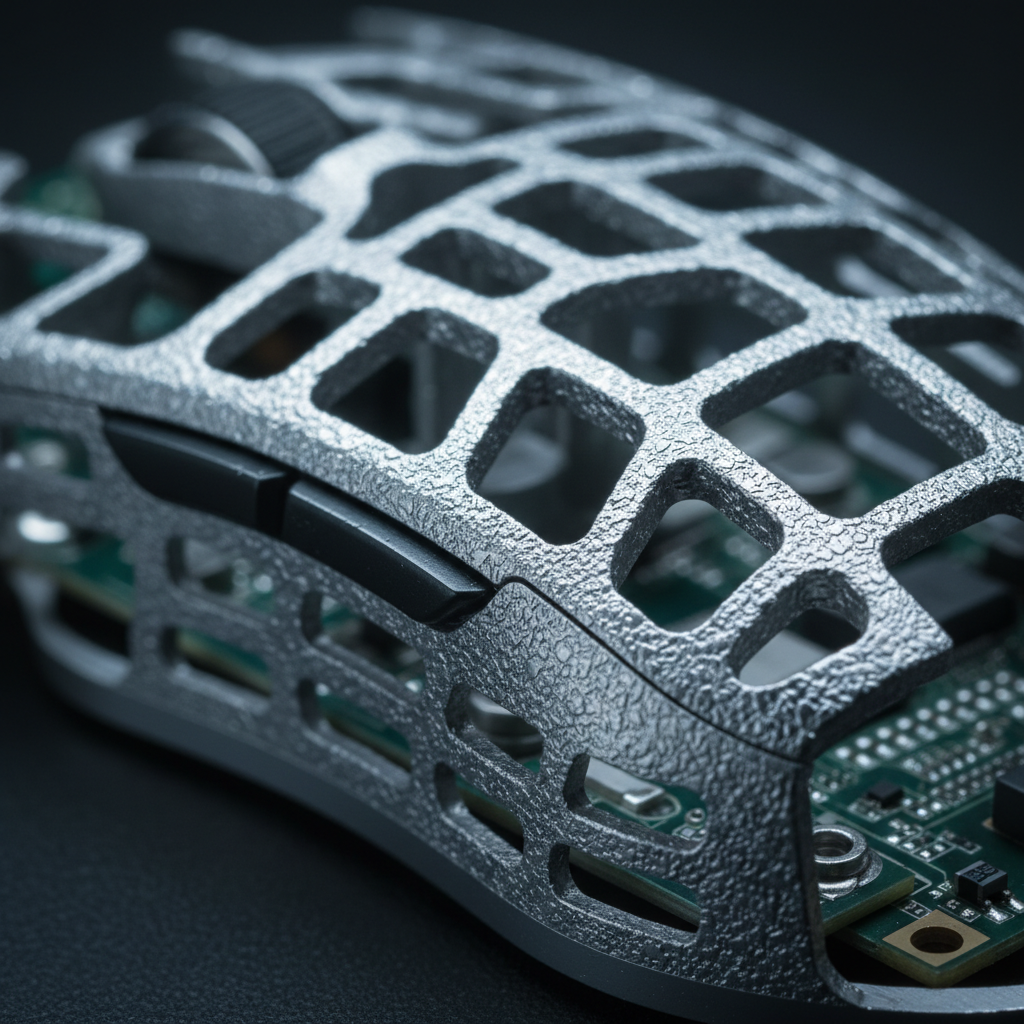

The shift toward ultra-lightweight gaming peripherals has driven engineers to explore materials far beyond traditional ABS plastics. Magnesium alloy has emerged as a premier choice for competitive mice, offering a strength-to-weight ratio that allows for sub-50g designs without sacrificing structural integrity. However, this transition to metal shells introduces a unique acoustic challenge: metallic resonance, commonly referred to by enthusiasts as the 'ping.'

Understanding why a magnesium alloy mouse might produce a ringing sound requires a deep dive into material science, structural acoustics, and the mechanical transmission of energy during a click event. This analysis examines the variables that contribute to this phenomenon and the engineering strategies used to mitigate it.

The Material Science of Magnesium Alloys

Magnesium is the lightest structural metal available, but its acoustic properties differ significantly from the polymers used in standard mouse manufacturing. In the context of gaming peripherals, two primary alloy grades are commonly utilized: AZ31 and AZ91.

AZ31 vs. AZ91: Acoustic Characteristics

The specific alloy grade plays a significant role in how a mouse shell vibrates. AZ31, often used in forged or CNC-machined shells, possesses a finer grain structure. While this enhances tensile strength, engineering principles suggest that more uniform structures can allow vibrations to propagate with less internal resistance, potentially resulting in a clearer, more sustained 'ping' compared to softer materials.

In contrast, AZ91 is typically used in die-cast variants. The die-casting process often results in a microstructure that may differ from forged equivalents. These internal structural differences can act as natural damping agents, absorbing a portion of the vibrational energy and shifting the acoustic profile toward a lower, more muted sound rather than a high-frequency ring.

Manufacturing Methods and Resonance

The method of fabrication further influences the acoustic signature. CNC (Computer Numerical Control) machining removes material from a solid block, maintaining the high density of the original billet. Die-casting, while more cost-effective for mass production, can introduce micro-voids that disrupt the path of sound waves. According to industry analysis on peripheral manufacturing trends, there is a growing shift toward hybrid manufacturing to balance the rigidity of forging with the acoustic damping properties required for high-end peripherals.

The Structural Acoustics of Thin Shells

In the pursuit of the lowest possible weight, engineers often push shell thickness to its physical limits. However, there is a critical tipping point where structural acoustics become a liability.

The "0.8mm Rule of Thumb"

A common observation among peripheral engineers and modders is that a shell thickness below approximately 0.8mm tends to increase the likelihood of high-frequency ringing. When the shell is this thin, it behaves less like a rigid body and more like a resonant diaphragm. While specific resonant frequencies depend on the exact shape and alloy, the natural resonance of an ultra-thin magnesium shell is typically observed in the 1,000 Hz to 4,000 Hz range.

This frequency range is particularly problematic for two reasons:

- Human Auditory Sensitivity: The human ear is most sensitive to frequencies roughly between 2 kHz and 5 kHz. A ping in this range is perceived as louder and more 'piercing' than a low-frequency vibration.

- Microphone Interference: Many condenser microphones used in gaming headsets have high sensitivity in the 2-5 kHz band. This explains why a faint metallic ping, which the user might barely notice, can sometimes be picked up by voice communication software.

Internal Geometry and Ribbing

To combat resonance in thin-walled shells, engineers employ internal ribbing or cross-bracing. By strategically increasing the thickness in specific areas (often targeting >1.2mm in critical zones), the resonant frequency of the shell is shifted lower. This displacement moves the sound out of the most sensitive auditory range, making any remaining vibration feel more 'solid.'

The Transmission Path: From Switch to Shell

The 'ping' does not originate from the magnesium itself; it is an excited response to the energy released during a mouse click. The path this energy takes determines the intensity of the resonance.

The PCB as an Intermediary

The Printed Circuit Board (PCB) acts as the primary bridge between the mechanical switch and the metal chassis. In a standard 'rigid mount' configuration, the PCB is screwed directly into the magnesium shell. This creates a high-efficiency transmission path for vibrations. When the switch bottom-outs, the impact energy travels through the switch housing, into the PCB, and directly into the shell's mounting points, which then act as a sounding board.

Isolation and Gasket Mounting

To break this transmission path, some high-performance designs utilize mechanical isolation. By using gasket mounts or floating PCB architectures, engineers can decouple the switch energy from the external shell. According to testing methodologies outlined by RTINGS, while the primary focus is often on click latency, the physical mounting of the switch also impacts the overall tactile and acoustic consistency of the device.

| Mounting Type | Energy Transmission | Acoustic Profile | Tactile Feedback |

|---|---|---|---|

| Rigid Screw Mount | High | Sharp, prone to ping | Crisp, direct |

| Gasket Mount | Low | Muted, deeper | Softer, dampened |

| Hybrid (Ribbed) | Moderate | Controlled resonance | Balanced |

Engineering Solutions: Damping and Nodal Tuning

Simply adding mass to a mouse to stop it from ringing defeats the purpose of using magnesium. Instead, engineers must use precision damping techniques.

Viscoelastic Polymer Damping

A highly effective factory-installed solution involves the strategic placement of viscoelastic polymer pads (materials that exhibit both viscous and elastic characteristics when deformed). Unlike standard foam, these materials dissipate vibrational energy as heat.

Rather than lining the entire shell, these pads are placed at the nodal points—specific areas where the shell's vibration is minimal or where damping is most efficient at killing the standing wave. While exact noise reduction varies by design, effective nodal damping can significantly reduce the audible decay time of the ping.

Key Terminology:

- Viscoelastic: A material property (like memory foam or Sorbothane) that resists shear flow and strain linearly with time when stress is applied. Ideally suited for shock absorption.

- Nodal Point: A point along a standing wave where the wave has minimum amplitude.

- Gasket Mount: A mounting style where the plate or PCB is held between soft gaskets rather than screwed directly to the case, isolating vibrations.

The Tuning Trade-off: Sound vs. Feel

There is a delicate balance between acoustic purity and tactile feedback. Over-damping a magnesium shell can lead to a 'muffled' or 'mushy' click feel, which competitive players often dislike. Engineers typically aim for a target sound pressure level (SPL) where the ping is masked by typical environmental noise. A common design target is to keep stray resonance below 50-60 dB SPL (measured at ~10cm), ensuring the mouse feels premium without becoming a distraction.

Quick Diagnostic & Fix Guide

For non-engineers, identifying and fixing "ping" can be simplified into a few actionable steps.

1. The Tap Test (Diagnosis)

- Step 1: Hold the mouse by the sides, lifting it off the mousepad.

- Step 2: Lightly tap the top shell with a fingernail near the scroll wheel and palm area.

-

Step 3: Listen for a high-pitched "ringing" tail that lasts longer than the tap itself.

- Thud/Click: Normal.

- Ring/Ping: Indicates resonance.

2. The Recording Check (Verification)

- Method: Use a smartphone voice recorder or PC microphone placed 10-15cm from the mouse. Record 5 single clicks.

- Analysis: Look at the waveform. A sharp spike followed by a flat line is good. A spike followed by a "fuzzy" tail indicates ringing energy (typically 2-4kHz).

3. Simple User Mitigations

- Grip Tape: Apply grip tape to the main buttons and sides. This adds mass and disrupts the vibration of the thin shell walls.

- O-Rings (Advanced): If the mouse design permits, placing small rubber O-rings on the mounting screws can act as a makeshift gasket mount (Note: This may alter sensor lift-off distance).

- Modding Tape: A small square of electrical or aluminum tape inside the top shell (if accessible) can change the resonant frequency.

Regulatory Compliance and Performance Standards

When evaluating a magnesium alloy mouse, technical specifications extend beyond the shell material. The integration of high-polling sensors and wireless protocols must meet strict global standards to ensure both performance and safety.

Wireless Integrity and Shielding

Magnesium shells can act as a Faraday cage, potentially interfering with 2.4GHz wireless signals. Manufacturers must carefully design antenna placement and ensure compliance with FCC Equipment Authorization requirements. Users can often verify the internal shielding and antenna configuration by searching the FCC ID (often using Grantee Codes like 2AZBD) to view internal photos and RF exposure reports.

Battery Safety in Metal Enclosures

Because magnesium is a thermally conductive material, battery management is critical. Per the IATA Lithium Battery Guidance, devices containing lithium-ion batteries are subject to strict transport regulations (UN 38.3). The metal shell actually provides a safety benefit here, acting as a more effective heat sink than plastic, which helps maintain lower battery temperatures during rapid 8K polling or intensive gaming sessions.

The Future of Metallic Peripherals

Magnesium alloy is no longer a niche material. As manufacturing techniques like thixomolding and advanced CNC refinement become more accessible, the 'ping' issue is being solved at the design level. By integrating acoustic simulation into the early stages of CAD development—similar to the processes used in high-end automotive engineering—manufacturers are creating mice that are both impossibly light and acoustically inert.

The transition from plastic to metal represents a significant leap in peripheral engineering. While the 'ping' is a natural byproduct of magnesium's physical properties, it is a manageable variable. For the competitive gamer, the trade-off of a few decibels of metallic resonance for a sub-50g, ultra-rigid chassis is a compromise that delivers a clear performance edge.

Disclaimer: This article is for informational purposes only. Modifying your gaming mouse, including opening the shell or adding internal damping materials, may void your warranty. Always refer to the manufacturer’s guidelines and local safety regulations regarding electronic devices and lithium-ion batteries. The acoustic thresholds (e.g., 0.8mm, 50-60 dB) mentioned are based on general engineering observations and may vary by specific device implementation.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。