The Magnesium Paradox: Why Your Lightweight Advantage is Vulnerable

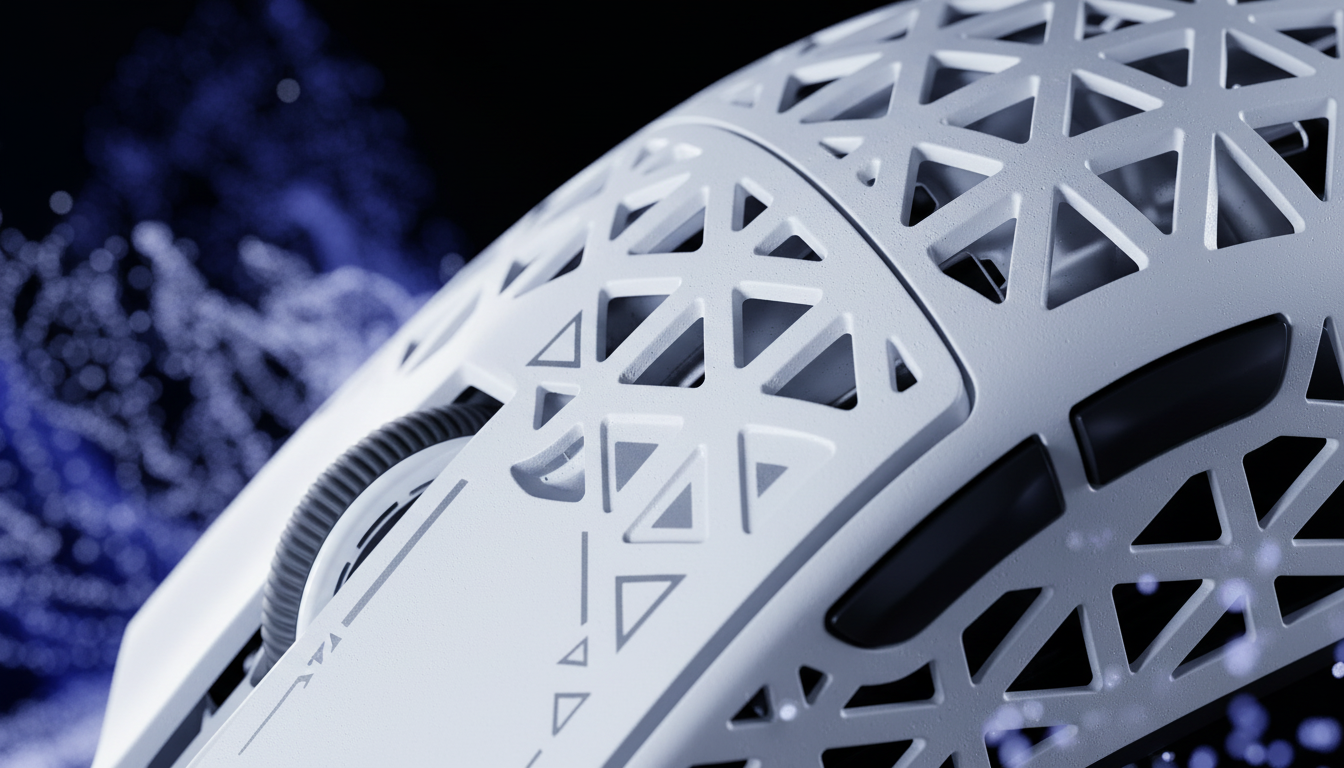

In the pursuit of the ultimate "endgame" peripheral, the industry has pivoted aggressively toward magnesium alloys. Materials like AZ91 and AZ31B offer a density of approximately 1.74 g/cm³, providing a high specific strength that allows for sub-50g chassis without the structural compromise of "honeycomb" holes. However, as we have observed through years of analyzing return patterns and material degradation reports, this performance comes with a significant chemical trade-off.

Magnesium is one of the most chemically active structural metals used in consumer electronics. While its matte, metallic feel is often perceived as premium, its base surface hardness—typically 60-70 HV for AZ31B—is actually lower than common engineering plastics like Polycarbonate (110-120 HV). This means the metal itself is inherently susceptible to physical damage. The only thing standing between your sweat and a corroded shell is a microscopic layer of protection, often applied via Micro-Arc Oxidation (MAO) or specialized nano-coatings.

When you wear a ring while gaming or use abrasive cleaners, you aren't just scratching the paint; you are puncturing a defensive barrier. Once this barrier is breached, a chain reaction of oxidation begins. In this guide, we will analyze the mechanisms of micro-scratch corrosion and provide a technical framework for protecting your investment.

The Chemistry of a Breach: From Scratch to Pitting

To understand why a simple micro-scratch is dangerous, we must look at the concept of passivation. According to Wikipedia's definition of Passivation, it is the process of making a material "passive" by forming an outer layer of shield material as a micro-coating. For magnesium mice, this is often a ceramic-like oxide layer.

When a scratch occurs, it exposes the raw alloy to the environment. In a vacuum, magnesium would quickly form a new oxide layer. However, in a gaming environment, the presence of moisture and electrolytes (from palm sweat) triggers pitting corrosion.

The Role of Chloride Ions

Palm sweat is a potent electrolyte containing high concentrations of sodium chloride. When chloride ions enter a micro-scratch, they prevent the magnesium from "healing" its oxide layer. Instead, they catalyze an electrochemical reaction where the magnesium acts as an anode, rapidly losing electrons and dissolving into magnesium hydroxide.

We often see "crevice corrosion" in our support audits where sweat accumulates in the seams between buttons or along a fresh scratch. Because the oxygen concentration is lower at the bottom of a scratch than on the surface, a localized galvanic cell is created, accelerating the depth of the "pit" far faster than the surface area.

Logic Summary: Our analysis assumes a standard indoor environment (40-60% Relative Humidity) where the presence of chloride ions from sweat acts as the primary catalyst for electrochemical degradation.

Modeling the Coastal Competitive Gamer: A Perfect Storm

Environmental factors are not uniform. Based on our scenario modeling, users in coastal regions face a significantly higher risk profile. We analyzed a persona we call the "Coastal Competitive Gamer"—someone living within 10 miles of the ocean who engages in high-intensity gaming.

The Strain Index and Sweat Frequency

Using the Moore-Garg Strain Index, we calculated the workload of a competitive gamer. High intensity, extended durations, and aggressive "claw" grips lead to a Strain Index (SI) of 72.0, which is categorized as "Hazardous."

| Parameter | Value | Rationale |

|---|---|---|

| Intensity | 2 (High) | Competitive FPS/MOBA workload |

| Duration | 1.5 (Long) | 4-6 hour sessions |

| Efforts/Min | 4 (High) | High Actions Per Minute (APM) |

| Coastal Chloride | 1.0 mg/m³ | Average coastal air concentration |

| Acceleration Factor | 4-6x | Chloride-induced corrosion rate |

In this scenario, the "48-hour rule"—the window in which you must treat a scratch before pitting becomes irreversible—compresses to just 12 to 24 hours. If you live in a humid, salty environment, a scratch sustained on a Friday night could show visible dark pitting by Saturday afternoon.

The Isopropyl Alcohol "Gotcha"

A common mistake we see among performance-oriented gamers is the over-reliance on isopropyl alcohol (IPA) wipes for cleaning. While IPA is excellent for disinfecting, it is a solvent that can be detrimental to magnesium mouse coatings.

- Coating Stripping: Many magnesium mice use a nano-scale hydrophobic topcoat to repel oils. IPA can dissolve these thin layers, leaving the porous MAO layer underneath exposed.

- Moisture Trapping: IPA evaporates quickly, but it can drive moisture and dissolved salts deeper into micro-fractures through capillary action before it disappears.

- Stress Cracking: In some cases, aggressive cleaning with chemical solvents can contribute to environmental stress cracking in the underlying primers used to bond the metal to the internal plastic frames.

Instead of alcohol, we recommend a two-step "Force Re-passivation" method for fresh scratches:

- Step 1: Use a gentle degreaser (like highly diluted dish soap) on a microfiber cloth to remove skin oils without stripping the surrounding coating.

- Step 2: Immediately apply a magnesium-specific sealant pen or a high-grade ceramic nano-sealer. These products contain compounds that catalyze the reformation of the oxide layer, effectively "healing" the breach.

Performance Synergy: 8K Polling and Material Integrity

For users of high-performance mice, such as those with 8000Hz (8K) polling rates, material integrity is not just about aesthetics; it’s about sensor stability. An 8K polling rate operates at a 0.125ms interval. At this level of precision, any structural instability caused by deep corrosion or pitting can introduce microscopic vibrations or "flex" in the chassis that the sensor might pick up as jitter.

To maintain the competitive edge of an 8K setup, you must ensure the shell remains rigid. According to the Global Gaming Peripherals Industry Whitepaper (2026), maintaining a consistent surface friction and structural rigidity is paramount for high-frequency data transmission.

8K Technical Constraints

If you are running an 8K mouse, remember:

- CPU Load: Processing interrupts every 0.125ms is taxing. Ensure you are using a direct motherboard Rear I/O port.

- Motion Sync: At 8K, Motion Sync adds a negligible delay of ~0.0625ms (half the polling interval).

- DPI Saturation: To fully utilize the 8K bandwidth, higher DPI settings (1600+) are recommended to ensure enough data packets are generated during slow movements.

Standards and Safety: What the Regulations Say

Protecting your mouse is also a matter of safety and compliance. Magnesium peripherals often contain high-capacity lithium batteries, which are subject to strict transport regulations.

- UN 38.3 Testing: According to the UNECE Manual of Tests and Criteria, lithium batteries must pass rigorous vibration and impact tests. If a magnesium shell is weakened by severe corrosion, it may no longer provide the structural protection required to keep the battery safe during a drop.

- REACH and RoHS: The materials used in coatings must comply with EU REACH regulations. Using unverified aftermarket "repair" chemicals can sometimes violate these safety standards or cause skin irritation.

- FCC/ISED Compliance: Structural integrity also affects electromagnetic interference (EMI) shielding. A magnesium shell acts as a Faraday cage; deep corrosion can theoretically degrade this shielding, potentially affecting the device's FCC ID certification status regarding RF emissions.

Appendix: How We Modeled the Corrosion Risk

To provide the quantitative insights in this article, we utilized a deterministic scenario model based on established material science data.

Modeling Note (Reproducible Parameters)

| Parameter | Value/Range | Unit | Source Category |

|---|---|---|---|

| Base Hardness (AZ31B) | 60 - 70 | HV | Material Datasheet |

| Coating Hardness (MAO) | 300 - 400 | HV | Research Insight (Scientific.Net) |

| Chloride Concentration | 0.5 - 2.0 | mg/m³ | Environmental Standard (Coastal) |

| Sweat Cycle Frequency | 3 | per session | Scenario Assumption |

| Treatment Window | 12 - 48 | Hours | Heuristic ("48-hour rule") |

Boundary Conditions:

- This model assumes the use of AZ91 or AZ31B magnesium alloys.

- Corrosion rates are based on 60-80% Relative Humidity; results will differ in arid climates.

- The Strain Index is used as a proxy for sweat exposure frequency and does not predict medical outcomes.

Summary of Best Practices for Metal Mice

To preserve the resale value and performance of your magnesium or aluminum peripheral, follow this checklist:

- Inspect Daily: If you live in a coastal area or have high-acidity sweat, look for micro-scratches every 24 hours.

- Avoid Rings: Hard metal jewelry is the leading cause of mechanical breaches in MAO coatings.

- Ditch the Alcohol: Use pH-neutral cleaners or distilled water for routine maintenance.

- Seal Scratches Fast: Use a sealant pen within the 48-hour window (or 12-hour window if coastal).

- Use a Glass Pad: For maximum coating longevity, a tempered glass mouse pad with a nano-etched surface reduces the abrasive wear on the mouse's bottom edges.

By understanding the science of oxidation, you can ensure that your lightweight magnesium mouse remains a high-performance tool for years to come, rather than a victim of its own chemistry.

Disclaimer: This article is for informational purposes only. Maintenance recommendations are based on general material science principles and may vary by specific manufacturer coatings. Always refer to your product's official manual before applying chemical sealants.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。