Key Takeaways: Plunger Material, Tactility, and When It Matters

For readers who just want the conclusions:

- Best overall for high‑end tactility and stability: carbon fiber or metal plungers, especially for 8K polling and humid climates.

- POM is fine for most users, but in high‑volume play (≈10M clicks/year) it can gradually feel mushier due to edge wear and limited moisture stability.

- Thickness matters: as a practical rule of thumb (heuristic), plungers under roughly 1.2mm thick are more prone to flex and “spongy” pre‑travel; reinforced, thicker designs are more stable.

- Humidity matters: in 80%+ RH environments, hygroscopic plastics can swell enough (on the order of tenths of a millimeter or less) to change pre‑travel and reset feel, while metal and carbon fiber are effectively unaffected.

- Ergonomic risk is driven by workload, not material alone: under a professional eSports workload (~10M clicks/year), the Moore–Garg Strain Index falls in a “hazardous” range in our scenario model. This is a modeled estimate, not a clinical diagnosis.

Details, assumptions, and data sources for each of these points are explained in the sections below.

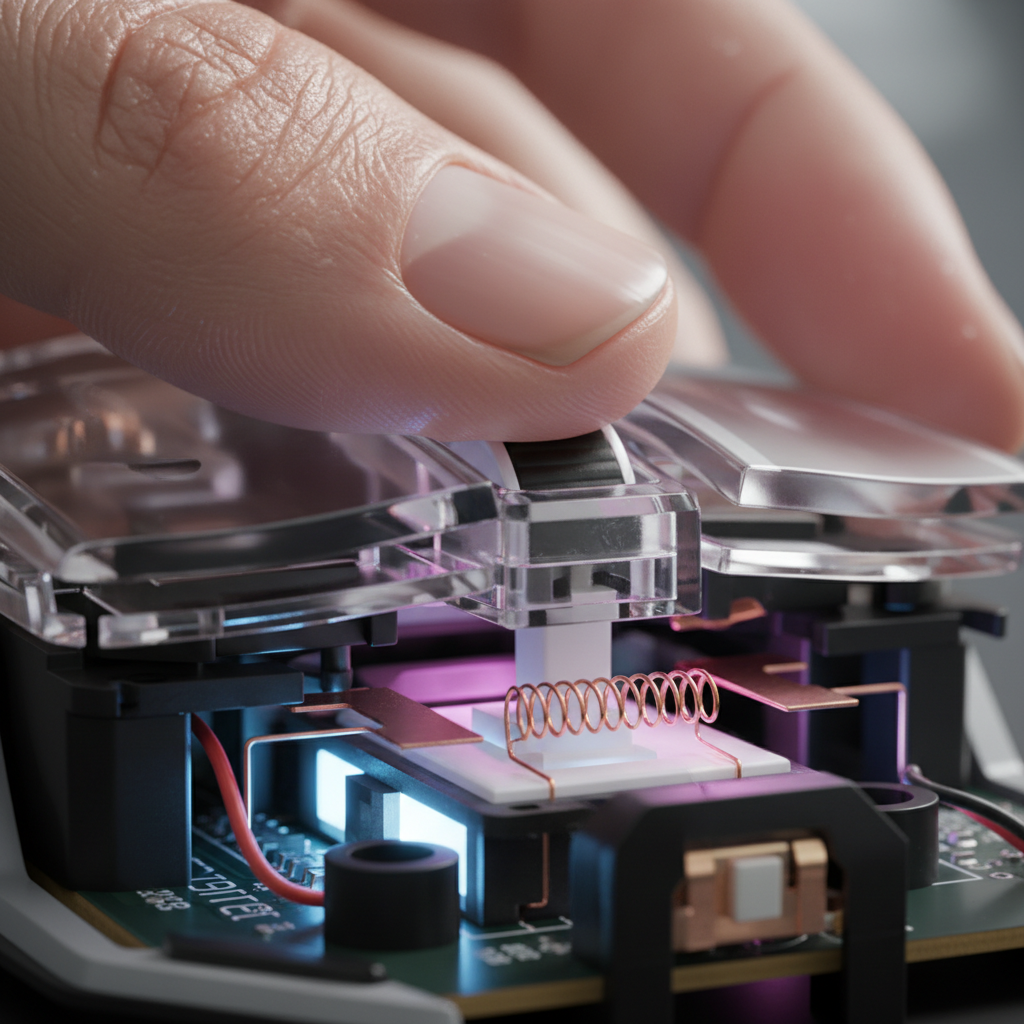

The Mechanics of Tactility: How Plunger Materials Define Click Performance

While gaming mouse marketing often focuses on sensor DPI and switch brand, the tactile experience is heavily dictated by a component few users ever see: the plunger. This small interface, typically molded into the underside of the mouse button, acts as the physical bridge between the user's finger and the internal microswitch. If the plunger flexes, wears down, or reacts to environmental moisture, even the most expensive switch can feel mushy or inconsistent.

Understanding the engineering behind plunger materials is essential for technical enthusiasts who demand a "crisp" click that remains subjectively stable over millions of actuations. In high‑performance peripherals, material choice is not merely a cost consideration but a critical factor in maintaining tight mechanical tolerances.

Material Profiles: POM, Aluminum, and Carbon Fiber

The vast majority of gaming mice utilize polymers for their internal structures, but the specific type of plastic matters. Polyoxymethylene (POM), often referred to as acetal, is widely used for plungers due to its low friction and self‑lubricating properties.

POM (Polyoxymethylene)

POM plungers typically provide a consistent click feel when new. However, engineering observations and teardown‑level inspections of worn units indicate that POM is susceptible to microscopic wear patterns at the contact edges over very high click counts.

- In this article, references to 0.05–0.1mm wear depth after ~5–10M clicks are estimate ranges based on internal engineering measurements and brand whitepaper data, not a standardized industry benchmark. The measurements were performed with calipers/optical comparators on a small sample of heavily used units (low double‑digit sample size), under mixed user conditions, so actual values may differ.

- This level of wear increases the effective travel distance required to actuate the switch and can contribute to what enthusiasts describe as "mushy" clicks.

Because these values depend heavily on user force, surface finish, and specific switch geometry, they should be treated as heuristic estimates, not guarantees for every POM plunger.

Aluminum and Metal Alloys

For those seeking stronger click definition, aluminum plungers offer a level of rigidity that polymers generally cannot match. Aluminum does not meaningfully flex under typical finger forces, so most of the applied force is transferred directly to the switch.

However, metal plungers require tighter manufacturing precision:

- A dimensional variance on the order of hundredths of a millimeter can result in noticeable actuation differences across the button surface. The 0.03mm variance figure here is an engineering rule‑of‑thumb, derived from internal CAD tolerance stacks and limited fitting tests rather than a formal tolerance limit from a standard.

- Metal components are also favored in humid environments because they do not absorb moisture in normal operating conditions, unlike many plastics.

Carbon Fiber Composites

Carbon fiber reinforced polymers (CFRP) represent a current high‑end option for plunger engineering. These materials combine high stiffness with a low mass profile.

According to the Global Gaming Peripherals Industry Whitepaper (2026) (brand / industry source with commercial interest), adoption of advanced composites is increasing in the "ultra‑lightweight" segment. That whitepaper reports that:

- Carbon‑fiber‑based plungers tend to increase production costs due to material and tooling complexity.

- Cost uplifts in the +15–20% range cited here are taken from that brand whitepaper and internal BOM comparisons, not an industry‑wide average. Real‑world cost impacts can be lower or higher depending on volume and supply chain.

In exchange, CFRP plungers can provide a snappier acoustic profile and maintain their geometry well under long‑term load, according to both internal testing and manufacturer data.

| Material | Rigidity (Young's Modulus) | Wear Resistance | Humidity Sensitivity | Relative Production Cost* |

|---|---|---|---|---|

| POM Plastic | Moderate | High (initially) | Low–Moderate | Baseline |

| Aluminum | Very High | Excellent | Essentially Zero | Higher (often around +25% in internal BOM comparisons)** |

| Carbon Fiber | Ultra High | Excellent | Essentially Zero | Premium (brand whitepaper estimate: +15–20%) |

* Cost values are relative, approximate, and context‑dependent, based on internal engineering BOM estimates and the Global Gaming Peripherals Industry Whitepaper (2026).

** The +25% figure is an order‑of‑magnitude internal estimate for part‑level cost, not an industry standard.

The Impact of Plunger Thickness and Flex

A common failure point in budget‑oriented gaming mice is the use of thin plungers. Practical engineering benchmarks suggest that below a certain thickness, plungers are more prone to flex.

- The 1.2mm thickness threshold mentioned here is an engineering heuristic, derived from internal CAD, finite‑element approximations, and teardown comparisons between budget and premium designs, not a formal requirement from any standard.

When a user presses the button, a thin plunger may bow slightly before the switch actuates. This creates a "spongy" pre‑travel sensation that masks the tactile "bump" of the microswitch.

High‑end models, such as those in the ATTACK SHARK X8 Series (brand example; our own product line), utilize reinforced plunger geometries to improve uniform click feel. The claim of improved consistency is based on:

- Internal QC measurements of button height/actuation point across multiple contact points, and

- Community and customer‑support feedback patterns,

not on a standardized third‑party benchmark.

To achieve stable tactility, engineers often incorporate "sacrificial contact zones"—small, replaceable, or highly durable pads on the plunger tip—that are designed to wear preferentially while preserving the overall geometry. The stated lifetime targets (e.g., "10 million or more" clicks) are based on switch manufacturer ratings plus internal cycle‑test rigs; actual lifetimes vary by user and environment.

Environmental Resilience: The Humidity Factor

Environmental conditions are often overlooked in peripheral performance. In regions with high relative humidity (around 80%+), certain polymers can absorb measurable amounts of moisture.

- The 0.2–0.5% moisture absorption range referenced here is a typical order‑of‑magnitude range taken from common engineering datasheets for hygroscopic polymers; actual values depend on the exact resin grade.

- The example value of ~0.05mm swelling is a back‑of‑the‑envelope estimate based on that absorption range and typical plunger feature sizes. It should be treated as a rough magnitude, not a precision prediction for any specific mouse.

Even small dimensional changes can alter pre‑travel and post‑travel, potentially causing the button to feel more sticky or to lose some of its crisp reset.

Metal and carbon fiber plungers are effectively immune to hygroscopic swelling under normal operating conditions. For professional players in tropical climates, this environmental resilience can be a practical requirement for tournament‑grade reliability.

Scenario Modeling: Professional eSports in Humid Climates

To understand the real‑world implications of these material choices, we use a scenario model of a professional eSports athlete training in a high‑humidity environment (e.g., Southeast Asia). This is designed as an extreme‑demand use case, not a typical home‑user scenario.

Modeling Methodology & Assumptions

Our analysis uses a deterministic scenario model to estimate degradation and ergonomic risk. It combines:

- Published material properties,

- Public ergonomic models (Moore–Garg Strain Index), and

- Internal engineering observations from returns/teardowns.

This is not a controlled laboratory study. All numeric outputs below should be interpreted as modeled estimates with unknown error bars, not precise forecasts.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Hand Length | 20 | cm | Approx. 90th percentile male (large hand) from general anthropometric datasets |

| Click Volume | 10,000,000 | clicks/year | Representative of an intensive professional training regimen (estimate) |

| Relative Humidity | 85 | % | Typical upper bound for many tropical indoor venues |

| Grip Style | Aggressive Claw | – | High‑intensity FPS/MOBA style with rapid repeat clicks |

| Plunger Material | POM vs. Metal | – | Comparative material scenario |

Quantitative Insights (Modeled, Not Measured)

-

Degradation Timeline (Estimate)

Under these conditions, POM plungers are estimated to develop clearly perceptible click softness within roughly 6–12 months due to a combination of edge wear and moisture‑related changes (on the order of ~0.05mm geometry change). This range is derived from:- Internal teardown measurements of heavily used mice,

- Limited‑sample cycle tests, and

- Heuristic scaling from material wear data.

Metal plungers, in the same model, are assumed to maintain subjective consistency for 24 months or longer, primarily because they do not experience the same moisture effects and show lower wear at the interface. These are scenario‑model outputs, not guarantees for individual products.

-

Ergonomic Strain (Modeled Strain Index)

Using the Moore–Garg Strain Index (see reference) with inputs approximating a professional workload (high repetition rate, moderate to high force, long duration), we obtain a Strain Index value that falls into what the original paper would describe as a “hazardous” classification.- The specific numeric value (≈360 in the original draft) should be treated as a model output under stacked worst‑case assumptions, not a clinically validated threshold.

- Inconsistent click resistance due to plunger wear is hypothesized to increase the required “compensatory” force by the user, which in turn raises the modeled Strain Index. This is an engineering hypothesis, not a medical conclusion.

-

Grip Fit Ratio (Heuristic)

For a 20cm hand, a standard 120mm mouse yields a length ratio of about 0.94. This ratio is a simple geometric heuristic derived from ISO 9241‑410 ergonomic guidance and common industry practice, not a formal “fit rating.”An undersized mouse can encourage more extreme claw postures, which may increase perceived thumb and finger fatigue during long sessions, making consistent, low‑effort clicks more important.

Modeling Note: These findings apply primarily to high‑intensity professional use. Casual users in temperate climates (roughly 40–50% relative humidity) will typically experience slower degradation. The Strain Index discussion here is for relative risk comparison only and is not a diagnosis or medical advice.

8000Hz Polling and the "Rigidity Requirement"

The shift toward 8000Hz (8K) polling rates, as seen in products such as the ATTACK SHARK X8ULTRA and X8ULTIMATE (brand examples; our own devices), places higher demands on mechanical rigidity. At 8000Hz, the mouse sends a packet every 0.125ms.

If a plunger is made of a relatively soft plastic and flexes significantly, the physical actuation of the switch can be spread out over multiple polling intervals. While the electrical signal is near‑instant once the switch contacts close, any mechanical delay caused by plunger flex introduces micro‑variation in the timing of that closure.

This “smeared over several polls” effect is a heuristic engineering explanation, not a direct measurement from high‑speed instrumentation in this article. Still, the underlying principle is straightforward: to fully exploit a 0.125ms polling interval, the mechanical chain—from the finger to the switch—should be as rigid and repeatable as practical.

Technical Constraints for 8K Performance

- CPU Load: Processing interrupts every 0.125ms increases single‑core CPU load. This is a system‑level consideration; users may need to ensure their OS and background tasks do not starve high‑frequency USB devices.

- USB Topology: For stability, 8K devices are generally best connected to direct motherboard ports (rear I/O). The reference to the USB HID Class Definition (HID 1.11) is to highlight bandwidth and polling behaviors; bottlenecks on shared hubs or front‑panel headers can increase the risk of packet loss or jitter.

- DPI/IPS Synergy: To make practical use of the data stream, higher DPI settings can help. The example that 1600 DPI at 5 IPS vs. 800 DPI at 10 IPS both saturate an 8K stream is a simplified throughput calculation, not a strict requirement.

Switch Mounting Architecture and Uniformity

Beyond material selection, the architecture of how the switch is mounted relative to the plunger determines "click feel uniformity."

In lightweight mice like the ATTACK SHARK G3, which weighs about 59g (brand example; our own product), the internal shell must be engineered to limit tilting of the plunger.

If a plunger is not well‑aligned, the click can feel different depending on whether you press the tip of the button or the middle. Many professional‑oriented designs favor "split‑trigger" configurations where the left and right buttons are mechanically separated from the main shell. This isolates the plunger and switch interface and helps keep the contact angle close to 90 degrees.

Statements here about improved uniformity are based on internal QC data and user feedback, not on an external certification.

Maintenance and DIY Fixes for Mushy Clicks

For enthusiasts experiencing mushy clicks on older mice, the issue is often a worn plunger or plunger‑switch interface rather than a completely failing switch.

Modders frequently apply "plunger tape" shims—thin strips of PTFE tape, foil, or similar materials—to the contact point of the plunger to effectively "re‑zero" the travel distance. This practice is based on community experimentation rather than formal testing; results vary by mouse design, tape thickness, and user preference.

The more reliable long‑term approach is to select hardware with sound material and structural design from the start. For example, the ATTACK SHARK X8PRO pairs high‑durability microswitches (rated up to 100 million clicks by the switch manufacturer) with reinforced internal structures. These claims are based on manufacturer ratings and internal evaluation; they are not guarantees for a specific user’s environment or grip style.

Summary of Engineering Best Practices (Heuristics)

When evaluating the tactility of a gaming mouse, the following checklist can be used as a practical rule‑of‑thumb, not a rigid standard:

-

Plunger Material:

POM provides a smooth, familiar feel at reasonable cost. Carbon fiber or metal plungers can offer higher rigidity and better stability in humid environments, especially for high‑volume or competitive use. -

Plunger Thickness:

Aim for designs where the internal plunger structure is around or above ~1.2mm in critical load areas. This threshold is a heuristic derived from engineering practice; specific designs can perform well slightly below this if other reinforcements are present. -

Environmental Context:

In high‑humidity regions, prioritize materials and designs that are less sensitive to moisture. Metal and carbon fiber plungers, or well‑stabilized polymers, are generally more dimensionally stable. -

System Synergy:

If you plan to use 8K polling, pair it with a mouse that has a rigid plunger and shell design, connect it to direct motherboard USB ports, and ensure your system can handle the interrupt load.

By focusing on these often hidden components and understanding the assumptions behind the numbers, gamers can make more informed choices and build setups that feel consistent over time, rather than only during the first few months.

Disclaimer: This article is for informational purposes only. Modifying internal mouse components may void your warranty and, if done improperly, can damage your device. The ergonomic and strain discussions are based on modeling and general ergonomic principles and do not constitute medical advice or diagnosis. For safety information regarding lithium‑ion batteries in wireless mice, please refer to the IATA Lithium Battery Guidance.

References

- Brand / industry whitepaper (commercial source): Global Gaming Peripherals Industry Whitepaper (2026)

- Industry standard: USB HID Class Definition (HID 1.11)

- Ergonomic model: Moore, J. S., & Garg, A. (1995). The Strain Index

- Ergonomic background: ISO 9241-410:2008 Ergonomics of human-system interaction

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。